The Secrets to Successful Resistance Fastener Welding

For the most part, the resistance-projection-welding (RPW) process is very similar to the spot-welding process. During spot welding, the size of the contact surface of the electrode cap determines current flow, while during RPW current flow is directed by the projections of the fastener. While AC and DC power sources suit RPW of fasteners, the choice of AC or DC depends on workpiece-material composition along with projection size and torque requirements.

Common Projection-Welding Challenges

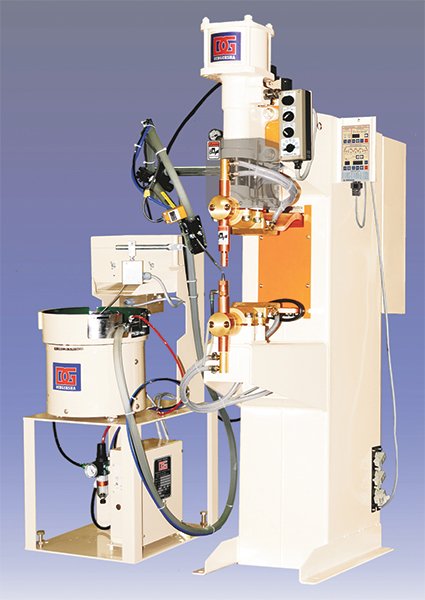

single-point projection-welding system combining a pedesal welder and nut/bolt feeder

To achieve a successfully projection-welded part, the welding machine must be correctly sized for the particular fastener being welded. The frame of the machine and the electrode assembly must be rigid to avoid flexure and misalignment under load. Shown: a single-point projection-welding system combining a pedestal welder and nut/bolt feeder.

While the basic process for the projection welding of nuts and studs may be simple, when fabricators fail to follow a few standard guidelines, several problems may occur. For instance, you might develop weld spatter in the threads, or experience hole misalignment. Cold welds and thread distortion also may occur.(…)

via Articles – The Secrets to Successful Resistance Fastener Welding | Metalforming Magazine.