Ann R. Thryft, Senior Technical Editor, Materials & Assembly

6/29/2016A new fixings and fastening system for assembling structural, load-bearing composite components promises 54% better adhesion, plus less weight and better mechanical performance than current composite fixing designs.

After five years of R&D, UK-based engineering and design company Adhesion Technologies Ltd. launched its new Spida Fixings and fastening system, combining fasteners with adhesives. It was designed to give OEMs and their Tier 1 suppliers in aerospace, transportation, and automotive industries a cost-effective system for fast assembly of composite, engineering plastic, and metal parts, using either metallic or non-metallic fixings.

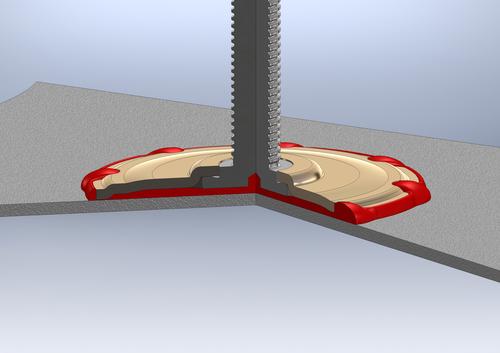

This sectioned Spida metal stud is welded to a Grippa base bonded to a substrate panel. Each Spida base uses Adhesion Technologies’ surface enhancement treatment technology on the bond interface, combined with a proprietary adhesion system and base design. Because the system actively redistributes cluster stress loads in the substrate the result is increased mechanical performance, in addition to better adhesion.

(Source: Adhesion Technologies)

According to a press release sent to Design News, Adhesion Technologies’ Spida Fixings and fastening system was designed by composites engineers. (…)

via Design News – Product News – Lighten Up Your Composite & Multimaterial Assemblies.