Company: HEICO Befestigungstechnik GmbH (Ense-Niederense, Germany)

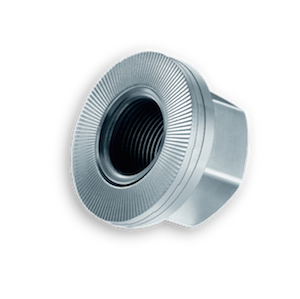

Product: HEICO-LOCK® Wedge Lock Nut, HEICO-LOCK® Wheel Nut

One year ago, after the successful market launch of the HEICO-LOCK® Wedge Lock Washers, HEICO introduced the HEICO-LOCK® Ring Lock Washers, which has been their youngest product so far. On the Fastener Fair 2014 in Hannover the introduction of HEICO’s newest product is going to happen. The HEICO-LOCK® Wedge Lock Nut and the HEICO-LOCK® Wheel Nut, which is designed especially for vehicles, add to the HEICO-LOCK® Portfolio for bolt securing systems. Customers can hope for big advantages especially in the user friendliness.

„We are proud of the work our developers were able to accomplish and we are really looking forward to presenting the results to our customers finally” said product development manager Frank Lutter, who feels very confident: „Our customers have already shown a great interest in our new product. That’s why we would like to invite everyone interested to come to Hannover and meet with us at our stand.“

DESIGN OF THE HEICO-LOCK® WEDGE LOCK NUT

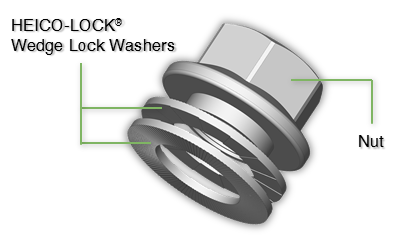

The HEICO-LOCK® Wedge Lock Nut provides a high-quality, user-friendly bolt securing system for the most demanding of applications and is ideal for repeated use. The captive and rotary combination of the nut and the original HEICO-LOCK® Wedge Lock Washers makes securing your bolted joints more efficient, effective and easier even under the most extreme vibrations and dynamic loads.

The HEICO-LOCK® Wedge Lock Nut is supplied preassembled. The nut and the HEICO-LOCK® Wedge Lock Washers are combined in a captive and rotary way, ensuring the HEICO-LOCK® Wedge Lock Washers and the nut are fixed permanently in the correct position with the wedge lock washers securing your bolted joint using the proven HEICO-LOCK® principle without loss of quality or function.

ADVANTAGES FOR YOU

The one piece design eliminates the risk of misuse.

Minimized risk of operating and production breakdowns caused by faulty bolted connections

Easy handling especially in hard to reach locations

Fixed permanently in the correct position

Reduction of assembly time and effort

Reduced complexity of the component due to less individual parts

Easy, safe and fast installation even for non-specialist users

Can be re-used without any reduction in function or quality

FUNCTIONAL PRINCIPLE OF THE HEICO-LOCK® WEDGE LOCK NUT

The securing principle of the HEICO-LOCK® Wedge Lock Nut and the HEICO-LOCK® Wheel Nut is based on preload instead of friction. Below, the functional principles are explained step by step:

1. Pre-asembled locking system

The HEICO-LOCK® Wedge Lock Nut is supplied pre-assembled and provides the user the clear benefit of always being in the correct locking position – particularly important if being installed and removed repeatedly

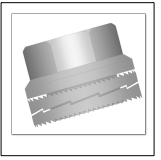

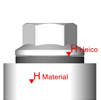

2. Difference in hardness: HHEICO > HMaterial

In comparison to the surface of the HEICO-LOCK® Wedge Lock Nut the surface hardness of the clamped parts has to be lower (class 8, class 10)

Hardness HEICO-LOCK® Wedge Lock Washers

Steel (through hardened) 485 ±25 HV0.3

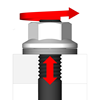

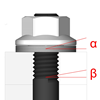

3. Difference in angles: α > β

3. Difference in angles: α > β

The wedge angle α between the HEICO-LOCK® Wedge Lock Washers is greater than the pitch β of the bolt thread

This angle means the expansion in thickness of the HEICO-LOCK® Wedge Lock Washers is greater than the possible longitudinal movement of the bolt along the thread

4. Difference in friction: μa > μi

4. Difference in friction: μa > μi

The wedge-shaped surfaces have a considerably lower friction coefficient μi than the toothed outside of the washers (friction coefficient μa)

Loosening due to dynamic loads causes movement between the two washers in the region of the wedge shaped surfaces

5. Difference in preload: Fdyn > Fstat

An expansion in thickness of the HEICO-LOCK® Wedge Lock Washers as a result of loosening leads to an increase in the clamping force

This causes an increase in the preload compared to the static state and thus causes the bolt to self-lock

HEICO UNTERNEHMENSGRUPPE

Since 1900, the HEICO Group has been providing reliable and high-quality solutions in the field of fastening technology and can thus draw on over 100 years of expertise. With more than 400 employees, the company manufactures a wide range of products which are distributed via our branches located throughout the world. Our global customer services and in-house laboratories offer a high level of technical advice as well as individual testing facilities.